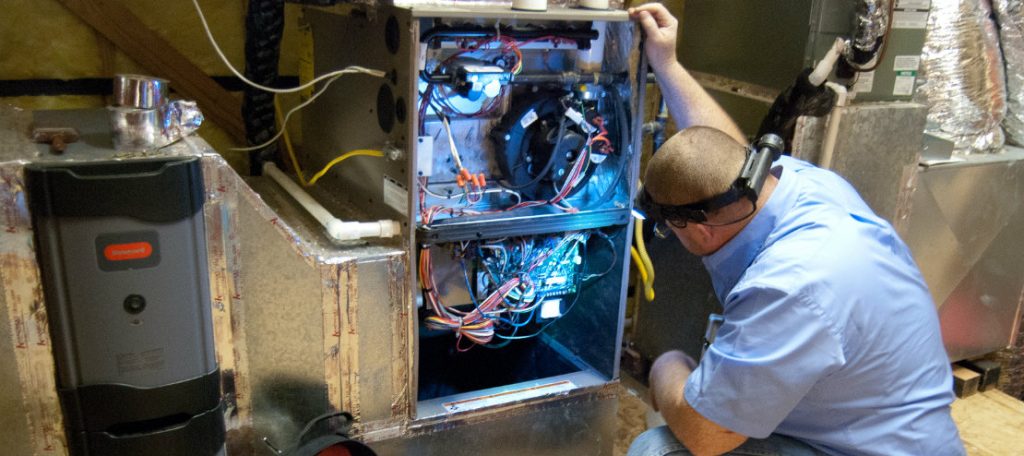

Make your HVAC system components run dependably for many years into the future by observing good maintenance of each and every one of them. You should have a trustworthy supplier of HVAC parts and supplies, in other words.

It’s because these individual parts won’t last forever and sometimes OEM isn’t an option because the original equipment manufacturer tends to intentionally render obsolete their wares 5-10 years after release.

The HVAC Parts to Watch Out For

HVAC refers to Humidifier, Ventilation, and Air Conditioner systems and devices that keep your home cold when it’s hot outside and hot when it’s cold outside. With that said, here are the HVAC parts you should get replacement parts for.

- Thermostat: Most thermostats last about a decade. From there, it could end up failing due to heat anticipator failure, dust build-up, or the wiring wearing out due to age. Once your thermostat starts malfunctioning, it should be replaced to avoid running the A/C at the wrong temperature.

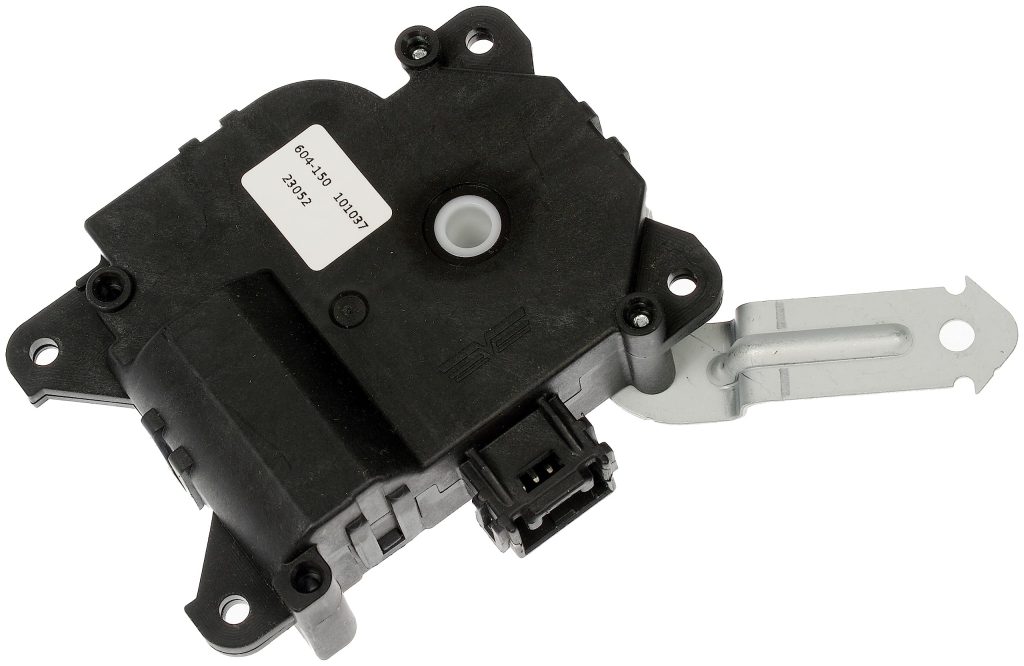

- Contactor and Capacitors: As for capacitors and contactors, these electrical parts assist in providing power to the entire HVAC system. They will go through wear and tear by bearing such huge loads. Once they start failing, you might hear the system fan working but don’t feel any cooling or heating happening.

- Igniter: In regards to the igniter, they’re the spark that ignites the fuel on any fuel-burning furnace necessary to make the heating part of the HVAC system to work. How long they can operate depends on how they’re designed. Some break down within 4 years while others last longer. Igniter failure is caused by debris, cracks, moisture issues, and voltage problems.

- Flame Sensor: The flame sensor protects you from carbon monoxide poisoning. It shuts off the furnace if fuel is escaping from the device but not burning like it should. You don’t want this item to fail on you because the results can be deadly. Usually, a good cleaning can fix it, but sometimes they can crack, rust, or otherwise fail.

- Blower Motor: The blower motor is the HVAC workhorse responsible for pushing cooled or heated air through your ducts. It can work for two decades or more. However, moisture or overheating can cause it to wear out early on before 20 years. It’s one of the more expensive parts of the HVAC system.

- Compressor: The most important part of the A/C is responsible for pressurization of the refrigerant before it is pumped right into the condenser. This part can fail because of incorrect refrigerant charge, damaged or blocked refrigerant lines, or dirty coils. It’s not cheap to replace this part, so it pays to maintain this part to maximize its operation lifespan.